INDUSTRIES & APPLICATIONS

Medical & Pharma

SUPERIOR PERFORMANCE

Enabling positive

human outcomes

For the Ultimate in Heat, Wear, Chemical Resistance, and Transparency

McDanel advanced material technologies provide the strength, durability, heat resistance, and clarity required in cutting edge medical research, laboratory, and pharmaceutical environments. Our glass containment products and solutions enable the analysis of low-volume, high-value microfluidic samples for life-saving applications at the forefront of human health.

medical & Pharma APPLICATIONS

medical laser & x-ray equipment

McDanel glass diffusers uniformly distribute and control high-intensity light and radiation for precise, consistent energy delivery. Their optical clarity, thermal stability, and resistance to harsh sterilization environments ensure reliable performance in diagnostic imaging, analytical instrumentation, and therapeutic systems.

RELATED PRODUCTS: Diffusers

precision instruments

McDanel glass and sapphire sight glass windows provide optically clear, chemically resistant viewing ports that maintain hermetic seals under pressure and sterilization conditions. Their durability, scratch resistance, and dimensional stability ensure accurate visual monitoring and consistent performance in critical processing, analytical, and diagnostic equipment.

RELATED PRODUCTS: Sight Glass Windows

medical laser equipment

McDanel alumina preionizer electrode tubes provide high-dielectric, thermally stable insulation for corona electrodes under high-voltage operation. Their precision, purity, and resistance to thermal and chemical stress ensure consistent preionization, stable laser pulses, and reliable performance in diagnostic, therapeutic, and analytical systems.

RELATED PRODUCTS: Preionizer Electrode Tubes

scintillator manufacturing

McDanel alumina and zirconia furnace components maintain structural integrity under extreme thermal cycles. Their thermal stability, wear resistance, and purity ensure precise processing conditions, consistent scintillator quality, and reliable long-term furnace performance.

RELATED PRODUCTS: Furnace Components

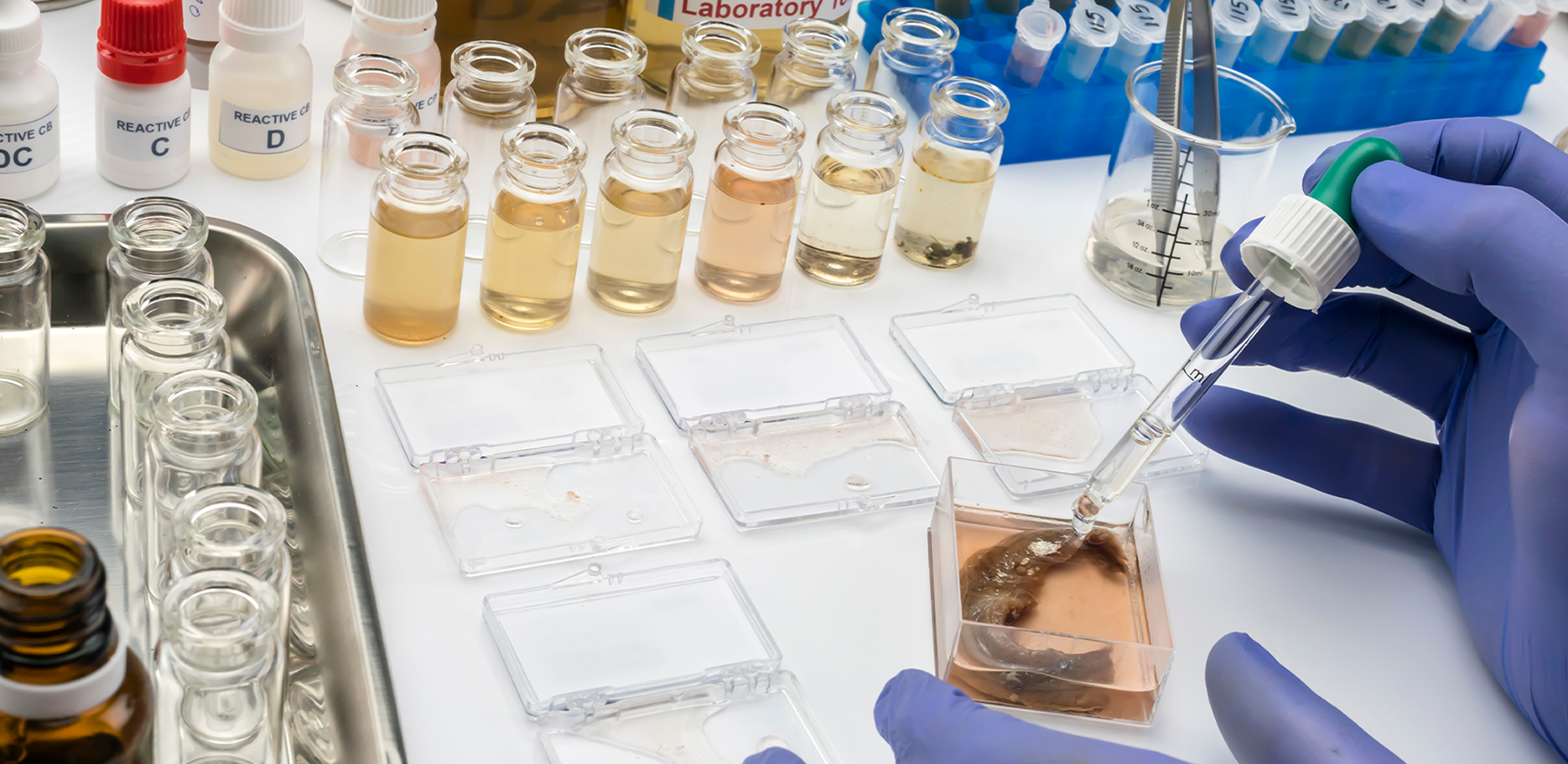

diagnostics

McDanel glass vials are chemically resistant, high-purity containers that preserve sample integrity for accurate testing and analysis. Their precise dimensions, clarity, and cleanliness support reliable handling, storage, and measurement in laboratory and point-of-care diagnostic applications.

RELATED PRODUCTS: Glass Vials

testing & delivery

McDanel glass vials and crushable ampoules provide secure, contamination-resistant containers for sample collection, storage, and controlled release of reagents or pharmaceuticals. Their precision fabrication and chemical durability ensure accurate dosing, reliable handling, and safe transport in laboratory, clinical, and production environments.

RELATED PRODUCTS: Glass Vials Crushable Ampoule

reagent packaging

McDanel glass vials provide chemically inert, high-purity containers that protect sensitive reagents from contamination and degradation. Their precise dimensions, clarity, and seal integrity ensure accurate dosing, safe handling, and reliable storage throughout laboratory, clinical, and manufacturing workflows.

RELATED PRODUCTS: Glass Vials

DNA Shearing

McDanel glass microtubes are precisely dimensioned, chemically inert containers that withstand high shear forces and thermal cycling without compromising sample integrity. Their clarity and consistency ensure accurate handling, efficient processing, and reproducible results in genomic analysis and molecular biology applications.

RELATED PRODUCTS: Glass Microtubes

Environmental & water quality

McDanel glass vials are chemically resistant, contamination-free containers for collecting and storing samples. Their precision dimensions, clarity, and seal integrity ensure accurate analysis, reliable sample preservation, and consistent results in laboratory and field testing applications.

RELATED PRODUCTS: Glass Vials

sample collection

McDanel drawn capillaries are ultra-precise, chemically inert tubes that allow accurate handling of micro-volumes of fluids. Their consistent inner diameters, smooth surfaces, and high purity ensure reliable sampling, minimal contamination, and reproducible results in laboratory and diagnostic applications.

RELATED PRODUCTS: Drawn Capillaries

opthalmic

McDanel glass vials from Richland Glass are high-purity, chemically resistant containers for storing and delivering sensitive eye medications and solutions. Their precise dimensions, clarity, and seal integrity ensure accurate dosing, safe handling, and reliable preservation of delicate ophthalmic formulations.

RELATED PRODUCTS: Glass Vials

protein packaging

McDanel glass vials are inert, contamination-free containers that protect sensitive proteins from glass-induced particulates and adsorption. Their precise, chemically resistant design ensures safe storage, accurate dosing, and long-term stability of biologic formulations.

RELATED PRODUCTS: Glass Vials

QUALITY, SERVICE & TECHNOLOGY

The MCDanel Difference

001

McDanel solutions are employed in laser surgery tools, particularly in components that must withstand high-energy laser beams because they maintain structural integrity and optical properties under harsh conditions.

Superior heat resistence &

stability

002

Endoscopes, laser systems, and diagnostic equipment require optical clarity and durability under intense use. McDanel sapphire and glass windows are particularly valuable for their scratch resistance and transparency, critical for precision instruments.

High Strength & Biocompatible

003

McDanel custom pressure-resistant glass components are used in high-pressure reactors and sterile environments for drug development and chemical processing.

Safe, reliable & accurate

004

Ceramics are employed in the manufacturing of ultrasonic transducers and piezoelectric sensors for medical imaging equipment, enabling high-quality imaging and diagnostics in healthcare settings.

Maximum insulation Capabilities

005

Critical laboratory equipment utilizes instrumentation containing ceramic insulators as well as crucibles, furnace tubes, and sample holders. Demand for McDanel ceramics hinges on their outstanding resistance to high temperatures, chemicals, and wear.

Chemical & wear resistance

006

Glass vials and components are essential to high-precision lab workflows and biotech R&D, including DNA for next-generation sequencing.

Enables advanced analytical workflows

007

Glass tubing, ampoules, flow-restrictors, pump components, glass-to-metal sealed stems and feedthroughs are used in fluidic systems, microfluidic analysis, and other high-precision scientific instruments.

advanced Containment solutions

008

Custom glass consumables for analytical instruments and diagnostic devices are essential in life-sciences labs, biotech, and clinical diagnostics.